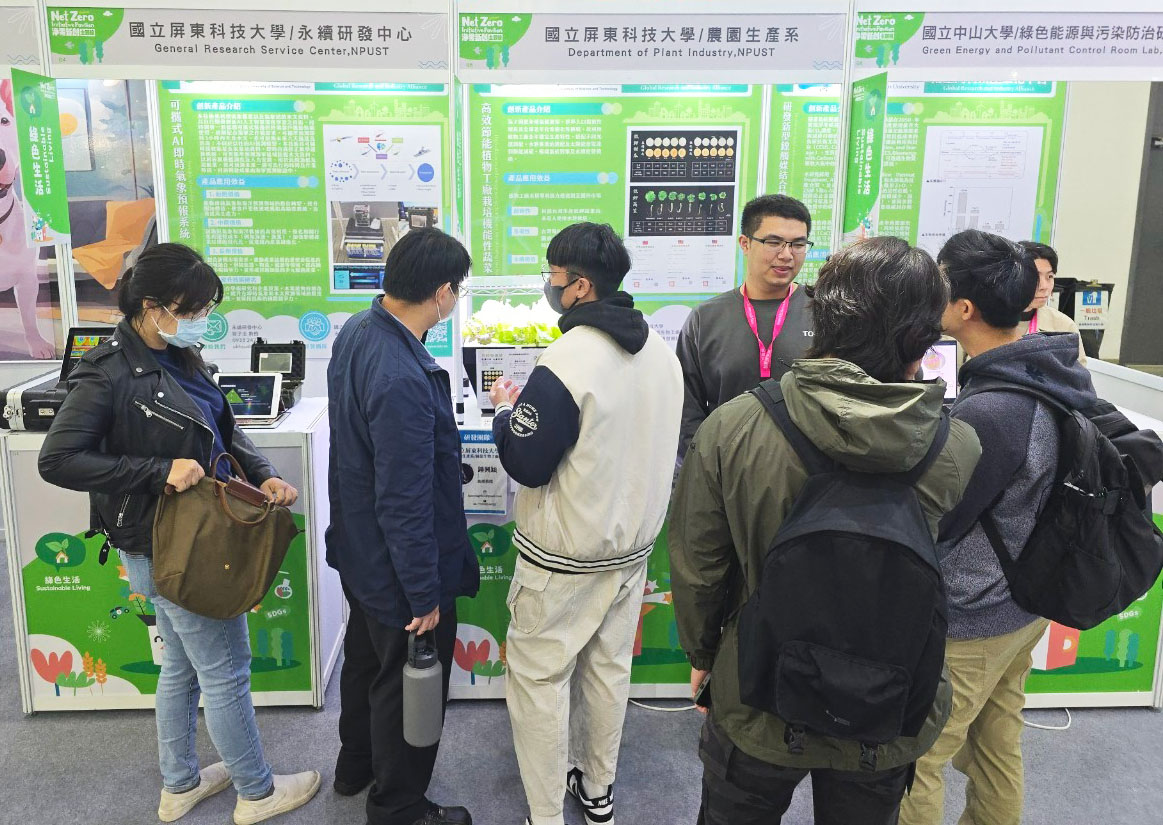

From March 20th to 22nd, National Pingtung University of Science and Technology (NPUST) exhibited two cutting-edge technological achievements at the Net Zero Initiative Pavilion of the 2025 Kaohsiung Smart City Expo. The innovations on display included a portable real-time AI weather forecasting system and an energy-saving plant factory for cultivating vegetables. The exhibition was a chance to share the school’s cross-domain integration and innovative R&D capabilities in the fields of smart disaster prevention and smart agriculture, and to further its commitment to public safety, net zero sustainability, and healthy and smart lifestyles.

Using Real-Time Data and AI to Provide Reliable Weather Forecasting

The portable real-time AI weather forecasting system was developed by Professor Hudson Hsu of the NPUST Sustainable Circular Economy R&D Center. It integrates hydrological data from meteorological satellites and meteorological ground stations and is equipped with the team’s self-developed AI deep learning algorithm. It can accurately predict weather and hydrological changes within the next 3 hours and provide wind speed and wave height forecasts for the next 6 days. With real-time data reception and an automatic correction computing module, the system allows for significantly improved prediction accuracy over traditional models. It has a wide range of applications and has a low-cost and portable design which allows for easy deployment. The Taiwan Navy has verified its reliability and confirmed its suitability for planning fishing vessel and yacht operations.

Highly-Efficient Green Energy Plant Factory Quadruples Production Capacity

The High-Efficiency Energy-Saving Plant Factory was developed by a team working under Assistant Professor Hsing-Ying Chung from the Department of Plant Industry. It incorporates LED spectrum control, hydroponic nutrient feeding and solar panel power generation into a system that allows for stable production throughout the year. In response to the needs of domestic patients suffering from kidney disease, the team also developed a patented technology for growing low-potassium fruits and vegetables, thus providing new options for healthy eating. In an area of 300 square meters, the technology also allows for the plant density to increase from 25,000 plants to 100,000, and it shortens the cultivation period from 50 days to 35 days—greatly improving production efficiency and use of resources. The Green Energy Plant Factory saves water, reduces reliance on fertilizer and combines renewable energy to effectively contribute to several sustainable development goals, including “Climate Action”, “Health and Well-being” and “Responsible Production and Consumption”.

Integration of Teaching and Research Promotes Talent Cultivation and Stimulates Innovation

During the exhibition, students from NPUST’s Smart Mechatronics Bachelor Degree Program and Department of Biomechatronics Engineering also visited the exhibition site to participate in guided tours and exchanges. Not only did the event help emphasize practical operational capabilities and industry-university integration, but it also gave students a deeper understanding of smart agriculture, AI meteorology, and net-zero technology, providing them with insights which will be of value to them on their future career paths.