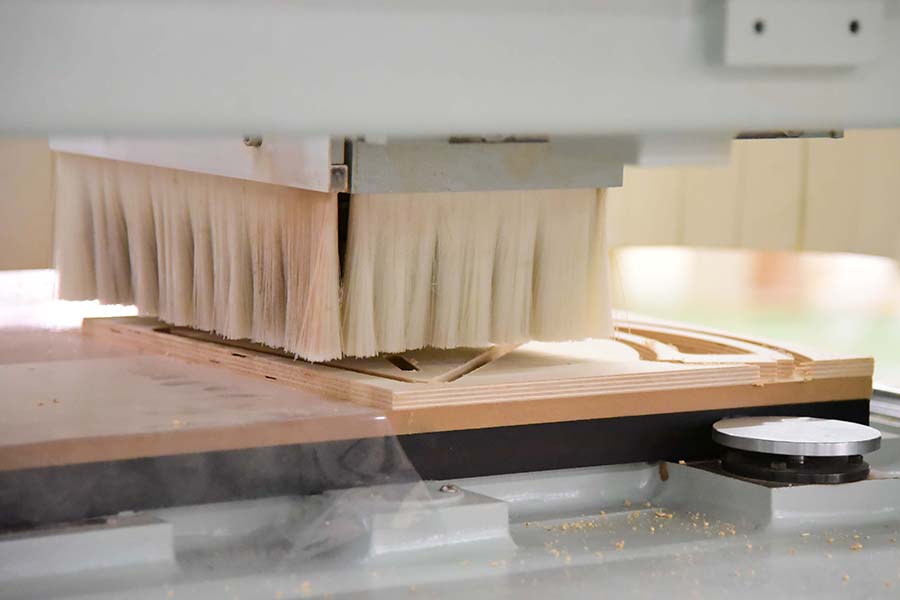

The NPUST Department of Wood Science and Design has just installed the brand new, cutting edge (pun intended) CNC wood processor and automatic blade changing system which were donated to the university to help train future wood-working professionals.

Chen Yanhong, who is the chairman of both the Taiwanese Home Furnishings Educational Foundation and Strongson Furniture Co., Ltd. initiated the cause –and together with Vietnamese Greatree Industrial Corporation and Anderson Industrial Corp., acquired the state-of-the-art equipment for the school.

On February 2, a donation ceremony was held at the university’s wood processing factory, with representatives of each of the organizations and the university in attendance. NPUST President Chang-Hsien Tai expressed that “under the guidance of the teachers, students in the Department of Wood Science and Design have already demonstrated great results; and with these new pieces of advanced equipment, which were graciously donated to the school, we look forward to even greater things to come.”

At the ceremony department director, Prof. Jinsheng Lin and Assistant Prof. Jiannan Chen presented some of the results of their practical education activities and commented on new trends in wood-working. Director Lin explained that “smart processing has reached a new milestone—and the newly installed equipment will certainly be one of the important features of the department in the years ahead”.

This sentiment was echoed by the Chairman Yan-hong Chen, who expressed his understanding that “we are about to enter the era of Industry 4.0.— and students need access to advanced equipment to meet the needs of the future work place”. Hanchen Chen, the general manager of Greatree Industrial Corporation and Yi-Hsian Huang, general manager of Anderson Industrial Corp. also made some statements; expressing their approval of the work done at the university in talent cultivation and their expectations that the new equipment will contribute to their future competitiveness.

Single processing functions of traditional equipment often results in complex or monotonous production procedures. With new equipment, however, the industry trending away from these limitations, while also improving design and increasing efficiency.

With the capabilities of the new machines, in the future, students will be able to upload their technical CAD drawings into the system to quickly and accurately cut out the various components they need in the assembly of their works.